Direct Conversion of Biomass to Gasoline & Diesel: GTI Hydropyrolysis

The Gas Technoloogy Institute (GTI) is developing an advanced hydropyrolysis method for directly converting a wide range of biomass types directly to gasoline, diesel, and other high value fuels and hydrocarbons. The method is designated IH2, and utilises hydrogen scavenged from the biomass itself. IH2 product is very low in water and oxygen, and claimed to contain 3X the heating value of standard fast pyrolysis oils.

GTI’s Integrated Hydropyrolysis and Hydroconversion (IH2) technology, which converts biomass directly into cellulosic gasoline and diesel hydrocarbon blendstocks

GTI’s IH2 technology is an advanced pyrolysis technology which utilizes low pressure hydrogen together with a proprietary catalyst to remove virtually all of the oxygen present in the starting biomass. (During the pilot IH2 project, CRI/Criterion supplied the IH2 catalyst.)

Features of the process include:

Feedstock flexible;

Fast biomass heat up maximizes liquid yield;

Hydroconversion with catalysts produces low-oxygen, low-acidity liquids;

Polynuclear aromatic components are not formed;

Self-sufficient process requires no supplemental water or hydrogen; and

High-quality renewable gasoline and diesel products are produced.

GTI says that renewable gasoline (RG) produced by the IH2 process results in more than 90% lower greenhouse gas emissions than petroleum-based fuels.

Compared to conventional pyrolysis processes this efficient, balanced approach optimizes the energy used to convert a range of non-food feedstocks into renewable transportation fuels or chemicals, according to GTI. As a result, the technology is highly flexible and is economical for both small- and large-scale applications. _GCC

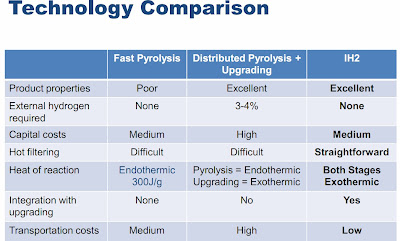

The table above compares the IH2 process with two competing pyrolysis approaches for biomass to fuels.

The diagram above provides a rough scheme for hydrogen flow in the system. The table below gives a brief step by step recipe for how the process aims to become self sufficient for hydrogen. The project is still firmly within R&D stages.

In the race to renewable fuels-from-biomass, it appears that the thermochemical approaches of gasification and pyrolysis have roughly a 10 year head start on microbial fuels -- in terms of achieving potential to scale up to compete with petroleum infrastructure. If GTI's approach provides all the benefits promised, and is ready for scale-up in 3 years, one can almost see the price ceiling descending over the liquid fuels landscape.

Pyrolysis and gasification are much faster and simpler than most biomass to energy processes -- except direct combustion of compressed or torrefied biomass. The GTI process appears to be an important advance over standard fast pyrolysis. GTI provides a time-to-market of roughly 3 years. That is not really such a long time to wait, given the promise.

More at EERE (PDF)

0 Comments:

Post a Comment

Subscribe to Post Comments [Atom]

<< Home