In a second reaction module, CMF is processed through one of two product manifolds. One of these, called "furanics" maintains furan ring of CMF intact, and the other, called "levulinics," is based on derivatives of levulinic acid (Figure 2). Both paths provide access to a variety of fuels, renewable polymers, and specialty chemicals. _azocleantech

One area of particular interest is in the context of processing of oilseed or algae feedstocks for the production of biodiesel. Using the above-described reactor technology, the product is a hybrid lipid/carbohydrate-based fuel consisting of a blend of fatty acid and levulinate esters. Using safflower seeds as a model, we have been able to increase the yield of fuel by 24%. This is accomplished by converting both the lipid and the carbohydrate content of the seeds into fuel. Not only is more biodiesel created in the process, but the blending of fatty acid esters with levulinate esters improves the fuel's cold-flow properties. _azocleantech

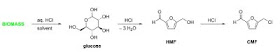

A general summary of the products in the CMF derivative portfolio is shown in Figure 4. Biofuels include substituted furans, tetrahydrofurans, and levulinate esters. These renewable fuels span the volatility range from diesel to gasoline, and are less toxic, more biodegradable, and cleaner burning than hydrocarbons. _azocleantechA growing number of research teams are looking at these HMF and levulinic acid derivatives in the hope of devising a profitable industrial scale process for conversion of cellulosic biomass to useful fuels. This approach is a refreshing change from the excessive focus on ethanol as biofuel. Clearly a wide range of renewable biofuels and biochemicals will prove far more useful than a two chain alcohol best known for its ability to relax human inhibitions.

Information on DMF fuel specifications here

No comments:

Post a Comment