Summary of Biomass Energy

A recent guest article at Biopact provides a very useful summary of terrestrial biomass energy, containing most of the important basic points of information about that resource.

The entire article is useful in providing a "pocket resource" for biomass energy. It is worth a full read.

There are many ways to generate electricity from biomass using thermo-chemical pathway. These include directly-fired or conventional steam approach, co-firing, pyrolysis and gasification.Notice the distinction between pyrolysis and gasification: Pyrolysis involves heating of biomass in the absence of oxygen, yielding pyrolysis liquids as well as gas and solids. Gasification involves the greater heating of biomass in a controlled, or limited oxygen atmosphere. This yields mostly gas with some ash. Both processes will become quite important over time. The gases from gasification--mostly CO and H2--can be converted to fuels and chemicals via fischer-tropsch synthesis and other chemical synthesis. The gases can also be fermented via micro-organisms to fuels and chemicals. Pyrolysis liquids can be refined to fuels and liquids as well.

1. Direct Fired or Conventional Steam Boiler

Most of the woody biomass-to-energy plants use direct-fired system or conventional steam boiler, whereby biomass feedstock is directly burned to produce steam leading to generation of electricity. In a direct-fired system, biomass is fed from the bottom of the boiler and air is supplied at the base. Hot combustion gases are passed through a heat exchanger in which water is boiled to create steam.

Biomass is dried, sized into smaller pieces and then pelletized or briquetted before firing. Pelletization is a process of reducing the bulk volume of biomass feedstock by mechanical means to improve handling and combustion characteristics of biomass. Wood pellets are normally produced from dry industrial wood waste, as e.g. shavings, sawdust and sander dust. Pelletization results in:1.Concentration of energy in the biomass feedstock.The processed biomass is added to a furnace or a boiler to generate heat which is then run through a turbine which drives an electrical generator. The heat generated by the exothermic process of combustion to power the generator can also be used to regulate temperature of the plant and other buildings, making the whole process much more efficient. Cogeneration of heat and electricity provides an economical option, particularly at sawmills or other sites where a source of biomass waste is already available. For example, wood waste is used to produce both electricity and steam at paper mills.

2.Easy handling, reduced transportation cost and hassle-free storage.

3.Low-moisture fuel with good burning characteristics.

4.Well-defined, good quality fuel for commercial and domestic use.

2. Co-firing

Co-firing is the simplest way to use biomass with energy systems based on fossil fuels. Small portions (upto 15%) of woody and herbaceous biomass such as poplar, willow and switch grass can be used as fuel in an existing coal power plant. Like coal, biomass is placed into the boilers and burned in such systems. The only cost associated with upgrading the system is incurred in buying a boiler capable of burning both the fuels, which is a more cost-effective than building a new plant.

The environmental benefits of adding biomass to coal includes decrease in nitrogen and sulphur oxides which are responsible for causing smog, acid rain and ozone pollution. In addition, relatively lower amount of carbon dioxide is released into the atmospheres. Co-firing provides a good platform for transition to more viable and sustainable renewable energy practices.

3. Pyrolysis

Pyrolysis offers a flexible and attractive way of converting solid biomass into an easily stored and transportable fuel, which can be successfully used for the production of heat, power and chemicals. In pyrolysis, biomass is subjected to high temperatures in the absence of oxygen resulting in the production of pyrolysis oil (or bio-oil), char or syngas which can then be used to generate electricity. The process transforms the biomass into high quality fuel without creating ash or energy directly.

Wood residues, forest residues and bagasse are important short term feed materials for pyrolysis being aplenty, low-cost and good energy source. Straw and agro residues are important in the longer term; however straw has high ash content which might cause problems in pyrolysis. Sewage sludge is a significant resource that requires new disposal methods and can be pyrolysed to give liquids.

Pyrolysis oil can offer major advantages over solid biomass and gasification due to the ease of handling, storage and combustion in an existing power station when special start-up procedures are not necessary.

4. Biomass gasification

Gasification processes convert biomass into combustible gases that ideally contain all the energy originally present in the biomass. In practice, conversion efficiencies ranging from 60% to 90% are achieved. Gasification processes can be either direct (using air or oxygen to generate heat through exothermic reactions) or indirect (transferring heat to the reactor from the outside). The gas can be burned to produce industrial or residential heat, to run engines for mechanical or electrical power, or to make synthetic fuels.

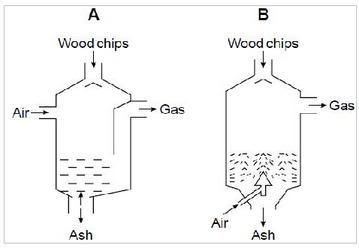

Biomass gasifiers are of two kinds - updraft and downdraft. In an updraft unit, biomass is fed in the top of the reactor and air is injected into the bottom of the fuel bed. The efficiency of updraft gasifiers ranges from 80 to 90 per cent on account of efficient counter-current heat exchange between the rising gases and descending solids. However, the tars produced by updraft gasifiers imply that the gas must be cooled before it can be used in internal combustion engines. Thus, in practical operation, updraft units are used for direct heat applications while downdraft ones are employed for operating internal combustion engines.

Figure 2 (click to enlarge): Schematic of updraft and downdraft gasifiers

Large scale applications of gasifiers include comprehensive versions of the small scale updraft and downdraft technologies, and fluidized bed technologies. The superior heat and mass transfer of fluidized beds leads to relatively uniform temperatures throughout the bed, better fuel moisture utilization, and faster rate of reaction, resulting in higher throughput capabilities. _Biopact

The entire article is useful in providing a "pocket resource" for biomass energy. It is worth a full read.

Labels: biomass

0 Comments:

Post a Comment

Subscribe to Post Comments [Atom]

<< Home