A recent story from Green Car Congress highlights a fascinating new approach to producing biodiesel that appears to be much better than the conventional transesterification approach, and different from Fisher Tropsch.

A recent story from Green Car Congress highlights a fascinating new approach to producing biodiesel that appears to be much better than the conventional transesterification approach, and different from Fisher Tropsch.NExBTL's approach uses a high pressure hydrogenation of fatty acids from either plant or animal sources. It should also be able to use animal offal from meat processing plants and abbatoirs.

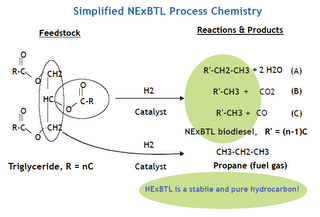

Neste Oil’s refinery-based proprietary NExBTL technology is based on the high-pressure hydrogenation of fatty acids. The product is a synthetic diesel fuel, free of oxygen and aromatic compounds. Side products include propane and gasoline. The process can use a flexible input of any vegetable oil or animal fat to produce a product with characteristics similar to Fischer-Tropsch output. (Earlier post.)More information and comments at the source.

The NExBTL process is different than both the transesterification process used to produced fatty acid methyl ester (biodiesel) and Fischer-Tropsch conversion used in BTL projects.

The trial, to start in fall 2007, will last until the end of 2010 and will embrace around 700 buses and 75 waste trucks. The aim is twofold: to reduce urban emissions and promote the use of biofuels on the road.

Vehicles in the trial will use either a 30% NExBTL – 70% conventional diesel oil mix or 100% NExBTL. Between 5,000 and 10,000 tons of the biofuel will be used annually, equivalent to 15-30% of the fuel used by buses and waste trucks in the Helsinki region. The trial includes the option to test other fuels for comparative purposes.

This public transport trial in Greater Helsinki is an important step for us, as it is a large-scale, highly visible and highly credible public initiative to test the operational and emissions performance of a second-generation biodiesel. We believe that our biodiesel will enable urban transport emissions to be cut significantly.

—Kimmo Rahkamo, Neste Oil Executive Vice President, Components

The trial will require national public funding, and an application will be lodged for a tax concession on the biocomponent to be used. Alternatively, use will be made of incentives linked to biofuel legislation planned for introduction in Finland in 2008 or an investment grant to cover the logistics costs involved.

Porvoo Refinery in July 2006. Photo: Suomen Ilmakuva Oy

The first NExBTL production plant is currently under construction at Neste Oil’s Porvoo refinery. With a rated capacity of 170,000 tonnes/year, the facility is scheduled to come on stream in summer 2007.

Neste Oil intends to extend NExBTL biodiesel trials to public transport in other EU capitals in the future. Neste Oil’s Board of Directors has approved a strategy aimed at making the company the world’s leading producer of second-generation renewable diesel fuel. The company also has NExBTL joint ventures with Total and OMV.

Comment excerpt:

In terms of feedstock, this competes against fatty acid methyl esters (FAME), known colloquially as biodiesel. Pure FAME is subject to biological contamination. Even blended, FAME is more aggressive toward certain vehicle fuel system components (filters, seals, Bosch unit injectors etc.) than mineral diesel - the vehicle manufacutrer may requrie a relatively inexpensive retrofit. The cloud point is relaitively high, though work on additives is bringing it down so FAME blends can be used in mild winter weather.

The Neste process yields alkanes rather than esters, meaning it can more easily be used for winter diesel blends. Instead of highly viscous glycerol, the by-product is propane gas, which can be used as a feedstock for the steam reformer that yields the neccessary hydrogen.

As noted in the comment above, the new process should make biodiesel more useful for cold weather use.

Eventually the modern world needs to move away from combustion style energy production, due to the chemical byproducts of combustion, but for the time being biofuels that can substitute for petro-fuels--even in combustion engines--will be extremely useful.

No comments:

Post a Comment